W.W. GAY Mechanical Contractor Inc. Adopts Novarc's Spool Welding Robot to Significantly Increase their Shop Productivity and Quality

Challenges that Forced them to Investigate New Solutions

W.W. GAY Mechanical approached Novarc because they needed:

-

To increase their productivity and efficiency to keep up with the fast track projects in their market

-

To find a way to increase productivity while increasing their quality as well.

-

To find an automated welding solution that would allow them to use junior welders and deploy their more experienced welders on other key projects.

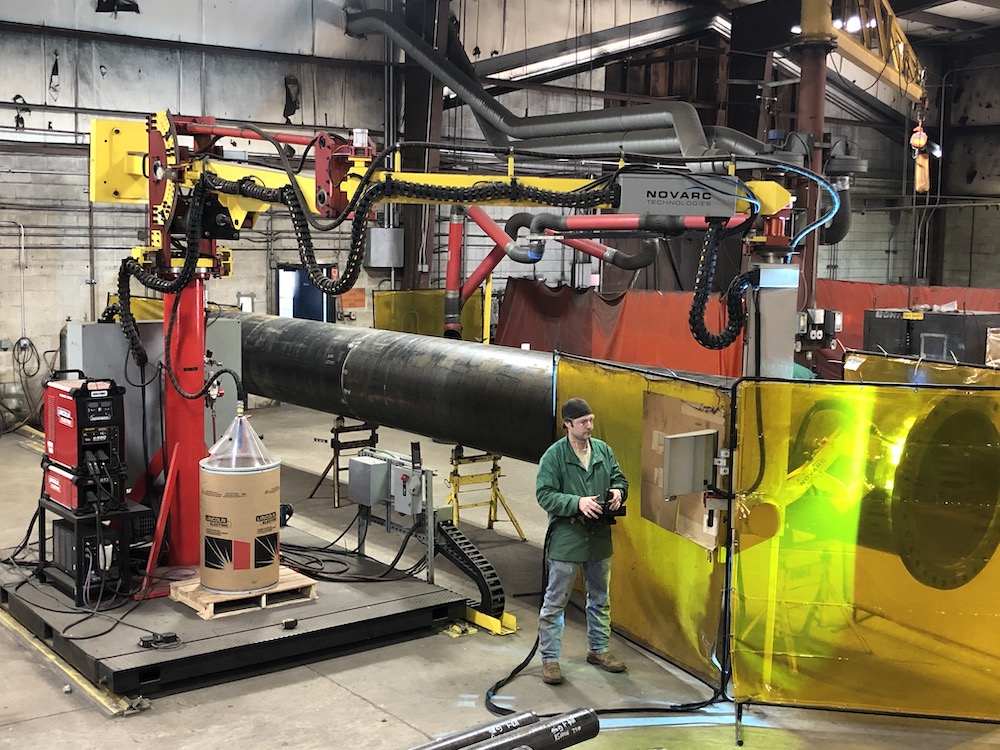

Novarc’s Spool Welding Robot (SWR) Solution

When they came across Novarc, W.W. GAY knew that they had found the right solution that would address all three challenges, and it didn’t take long before the SWR was implemented at their facility, and their operators were trained to use the robot.

Novarc’s Spool Welding Robot (SWR), a collaborative welding robot is designed specifically for pipe, small pressure vessel, and other types of roll welding. Being a collaborative robot, the SWR combats the shortage of highly qualified welders by working with a less experienced operator to significantly improve shop productivity, and produce high-quality welds every single time.

The Bottom Line

By implementing Novarc’s solution, W.W. GAY has been able to achieve over 200% increase in shop productivity, 100% Radiography Test (RT), and on some projects a 12x increase in weld productivity.

Productivity Improvements

Prior to purchasing the SWR, the team at W.W. GAY were welding between 80-100 diameter inches on average per shift using welding positioners with the GMAW/FCAW weld process; and they wanted to increase a welding bays’ inch count to the maximum amount that they could imagine.

“With the SWR, we have seen a tremendous increase of weld inches per shift from 6” and bigger. Depending on pipe size, we can hit inch counts anywhere from 200-275” on a regular basis with the SWR.” Says Ray.

“The fact that we can weld slip on flanges is probably one of the most impressive tasks that the Novarc SWR is capable of. Also, we have gotten really efficient at welding stainless steel fabrication with the SWR and this is helping tremendously with our efficiency. We have gained a lot of ground on everything that we weld on the SWR but one that stands out is the welding of stainless steel.

Our old way of welding stainless would be to TIG weld with using an ID purge. A 16” schedule 10 weld would take 2-1/2 hours or so to get a purge set up and then weld out. We now can do a 16” schedule 10 weld in 12- minutes that will pass RT.” Says Ray.

“We do our shop tours for any specific general contractor that we may be working for, they are really impressed when they see the speed and precision of the SWR. And when I explain how the SWR has improved our efficiency, it is a major eye opener at our capabilities to keep up with job flow needs and expectations.”

Quality Improvements

By being a collaborative robot, the SWR minimizes human error and therefore reduces the failure rate from the industry average of 3-5% to less than 1%, resulting in RT quality welds each time.

“The thing about the SWR is that it is a start-to-finish weld, once you hit the go button, it welds the root, fills and cap without stopping, which makes doing a weld that has to be RT’d a bit of a cake walk since there is no in between pass clean up and prep. We currently have a 100% pass rate with our RTs on the SWR. To put this into perspective, a 10” standard weight weld can be achieved in 12-minutes or so, which is highly remarkable.” Says Ray.

Reducing Dependence on Highly Skilled Welders

The SWR has reduced W.W. GAY’s dependecy on highly skilled welders, of whom there is a global shortage. The company currently has 3 trained operators, including a 3rd year apprentice, who are all equally efficient with running the SWR.

“It (the SWR) is head over heels better and more efficient, and the quality is amazing.” Says Jason Craven, Welder at W.W. GAY Mechanical Inc. “I’m completely comfortable using it, there are no problems at all. Once you get the hang of it, it is easy to use … they (Novarc) provided excellent training.”

About Novarc Technologies

Novarc Technologies is a Canadian-based robotics company specializing in the design and commercialization of collaborative robots for industrial applications. Novarc’s Spool Welding Robot (SWR) is the world’s first of its kind in pipe welding application. Novarc’s SWR has built a reputation for its unique form factor and advanced features for pipe welding not unlike a human’s precision and dexterity, with an operator-friendly user interface, adaptive control systems for accurate torch control, and machine learning algorithms to detect features.

As a proven pioneer in the field, Novarc has a dedicated team of engineers and scientists eager to solve challenging industrial automation problems that improve customers’ bottom line. The welding industry is looking to adopt these technologies in order to solve the shortage of qualified welders, accommodate the millennials workforce, and solve the cleantech challenges of this century.