“

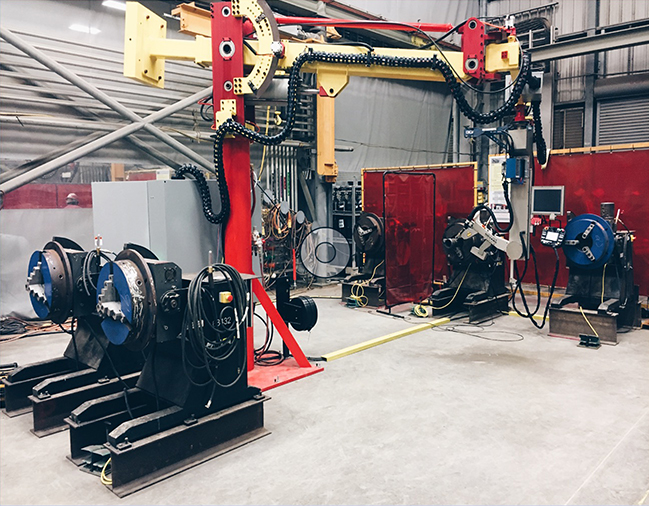

”Novarc machine brings a new level of quality and consistency with every weld as well as an embedded video of the weld into the BIM model.

Pitt Meadows Plumbing & Mechanical Systems Ltd.

“

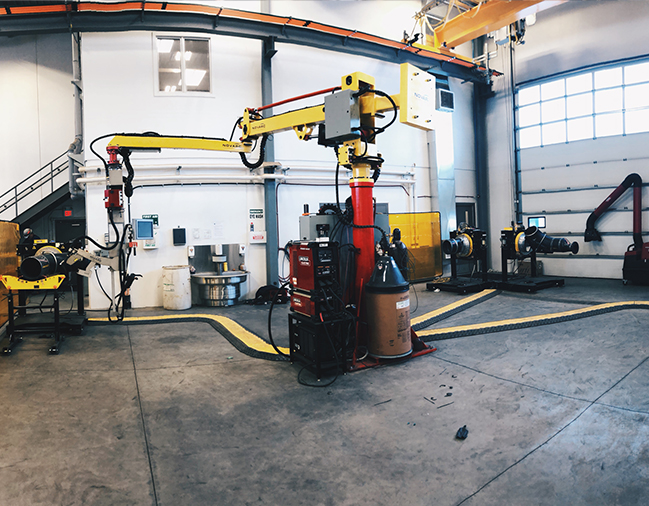

”Novarc machine brings a new level of quality and consistency with every weld as well as an embedded video of the weld into the BIM model.

Pitt Meadows Plumbing & Mechanical Systems Ltd.

“

The SWR would be my choice because it really takes all the hard work away from welding … I feel pretty comfortable using it. The support is great, a lot of help throughout. From the start they (Novarc’s team) have been there for everything.

Schweißer (Lehrling im 2. Ausbildungsjahr)

“

We’re doing 200 diameter inches/day and getting 100% x-ray quality and we think we can get 300 with the right project.

W.W. GAY Mechanical Contractor, Inc.

“

Since I am a welder, I know pretty well what somebody can get out of an 8 hour day; I think we can triple that with the SWR!

Betriebsleiter

“

I see the potential of this (SWR), not only where it is right now, but where it can go … In the end, it’s an exponential reduction in the cost and time.

Wade Eno

CEO of Robofab

“

Once you get it dialed in, it’s the same weld every time with the same quality and consistency. It (the SWR) is head over heels better than manual welding; more efficient, more production and like I said, the quality is amazing.

Schweißer

“

It’s a game-changer, and it’s welder friendly. We just have to figure out how to feed the machine faster.

Werkstattleiter

“

The equipment is working well. We are close to our target regarding the number of Di’s/week we want to weld with it… if we use it from root to cap, we would have a factor of close to 2.5:1 instead of 2:1.

Ganotec – Muga Fab

“

… these cutting-edge, collaborative robotic systems allow pipe welding tasks to be done dramatically more effectively and efficiently!

Seaspan Vancouver, Drydock Company Ltd.