1. What are the main features of the SWR?

Semi-autonomous

Using a laser scanner, point laser and closed-loop control systems, the SWR automatically maintains the torch to pipe distance with 0.1mm accuracy and assists the operator in seam tracking so primary focus can remain on the weld. Depending on the fit up, arc light, and spatters, additional operator input may be required for seam tracking and height control.

Collaborative

As a collaborative welding robot, the SWR is designed to meet all the safety requirements of ISO 15066; therefore, it does not require fencing or a safety cell. A junior welder can stand beside the robot and make changes during the weld as required.

Long Reach

Among industrial spool welding robots, the SWR has the largest ratio of reach to footprint. With a footprint of 16 sq ft, the SWR has a radial reach of 15’ which allows for welds in pipe modules and spools up to and including 30’.

Ergonomical

Designed for semi-automatic 1G roll welding, the SWR significantly improves the ergonomics of pipe welding by having the robot take on the heavy lifting of a consistent weave motion.

Production Monitoring

The SWR provides repeatability and reliability; The NovData™ logging software captures all available data for each weld pass for future analysis and reporting.

نوفاي نظام رؤية اللحام

The SWR is equipped with a welding vision system which can display the weld to the operator as it progresses and records a video from each weld for analysis and future production improvements.

2. What size of pipe can be welded with the SWR?

The base model of the SWR can weld pipes from 2” to 60” with appropriate pipe positioners.

3. Which welding process can be used?

The single torch SWR uses GMAW or MCAW from root to cap.

The dual torch SWR uses GMAW or MCAW for root, and MCAW or FCAW for fill and cap.

SWR uses modified short-circuit waveform on the root, that is STT, RMD or LSC.

TIG is currently not offered with SWR.

Talk to our sales team if you’d like to know more about your specific process.

4. What materials can be welded with the SWR?

The SWR can weld carbon and low alloy steels, as well as stainless and nickel alloys. The seam tracking and height control features are only available on carbon steel at this point. Recipe development for nickel alloys is incumbent on customers.

5. Does the SWR weld root to cap automatically? If yes, how do you deal with slag inclusion?

Yes, the SWR has the ability to switch between weld modes without shutting off the arc. The standard SWR process is GMAW with solid wire. The solid wire has moderate levels of silica (not heavy slag). This silica is burnt by the arc as the arc goes over it. Operators can see this throughout the weld process using the welding vision system.

6. Can I integrate my existing positioners with the SWR? Can I use the integrated positioners

that are not being used by the SWR in manual mode?

The SWR can easily be integrated to work with different positioners including Team Industries, LJ, Profax, and Preston Eastin. Our team can verify if we can integrate with your specific positioner, brand, make and model.

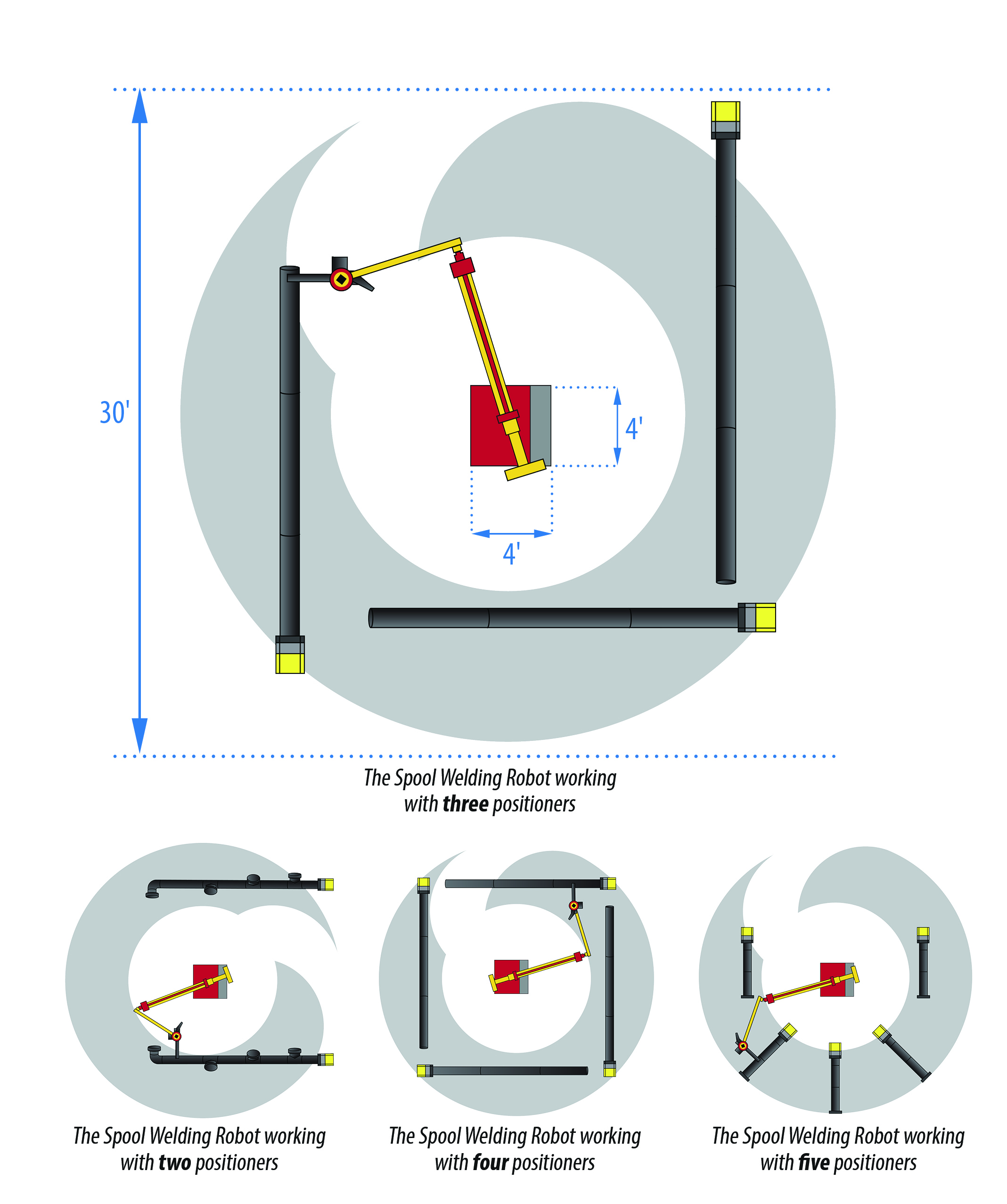

The robot has the ability to integrate with 2 to 5 positioners in a layout determined by you. The picture on the left shows some of the possibilities with 2, 3, 4 and 5 positioners.

Integrated positioners that are not being used for welding with SWR, can be rolled via foot pedals and used for pipe

preparation, tacking, grinding.

7. What power sources can be used with the SWR? Can I use my existing power source?

Power source options are Lincoln PowerWave® R450, Miller Auto-ContinuumTM 500, and Fronius TPS 400i LSC Advanced. All units are quoted with a power source.

8. What size root gap is used when welding and what are the tolerances?

The pipe/components are fit-up to a typical 3/32 in. (2.4 mm) root opening (gap) with a tolerance of ± 1/32″.

9. How does SWR deal with Hi-Lo on pipes?

SWR operators are trained to scan the pipe visually prior to the start of the weld for assessing the hi-lo, root gap and inspecting the tacks. If the Hi-Lo is higher than the amount specified by the SWR bevel requirements document, the pipe has to be refitted. If the Hi-Lo is within the allowed tolerances, the operator can enable the torch weave dwell functions. During the root pass, the operator can address the Hi-Lo using the asymmetric dwell and root save to weld the root. During the fill and cap passes, the operator uses the dwell function to manage the Hi-Lo. In this scenario, the laser-assisted seam tracking and height control have to be disabled for all passes to better allow the operator to control the torch

position.

10. How does SWR deal with fitting to pipe connections when thicknesses are different on the

two sides?

Similar to the Hi-Lo, SWR operators accommodate this scenario by enabling the dwell function on the thicker side of the joint prior to the start of the weld. If the inner diameters of the two sides do not match, operators have to grind down the inside to make sure the toes align as they would do in manual/semi-automatic welding. (Fittings are pre-heated prior to the weld).

11. Does the SWR fall under robotic welding from a welding procedure standpoint?

Based on industry standards, the SWR falls under mechanized welding, given that the operator interacts with the machine and makes on-the-fly adjustments.

12. What floor footprint is required for the SWR?

With a 4′ x 4′ footprint, the SWR has the smallest industry footprint where we typically see anything up from 7′ x 30′. Therefore, it does not cannibalize shop floor space and it won’t interfere with production flow.

13. How much productivity and capacity can I expect from using the SWR?

This depends on your current welding process. One SWR with an operator can produce the same output as 4 welders using SMAW, and 2-3 welders using manual root to cap GMAW.

14. Why does productivity improve with the SWR?

By eliminating the torch hand control, the mechanized weave relieves welder fatigue so they can expect a higher deposition rate, higher production, faster track speeds and the ability to run pre-programmed

welds.

15. What is the ROI on investing in an SWR unit?

With just a few details about your operation, we’ll have your ROI calculated. Typically our customers see an ROI of 6-18 months.

16. How does the SWR fit in the production flow?

The SWR is designed to fit in pipe fabrication shops because the height does not interfere with overhead cranes. In addition, the SWR can be easily parked away to allow shop traffic to pass.

17. How long does it take to install and commission the SWR?

Assuming an integration with two new positioners (from the approved list) , it takes two days to install the SWR and only one day to commission it.

18. How long does it take to train an operator and what skill level should they have?

It takes 3 – 5 days to train an operator for both operations and maintenance. Operators need to know the basics of pipe welding. We generally recommended training 3 – 5 operators with at least one journeyman pipe welder.

The operators should know the basics of welding and have some welding experience.

19. To which Code requirements can welding procedure specifications (WPS) be qualified with

the SWR?

The SWR has qualified multiple WPS to ASME Section IX requirements, including Charpy Impact testing with full mechanical testing (bend & tensile tests) and supplemental hardness testing. WPS can be developed for other codes, as required.

20. What weld quality requirements can be realized during production welding with the SWR?

The SWR produces consistent quality welds during production , characterized with low repair rates when non destructively tested with radiographic and ultrasonic examinations to typical ASME B31.1 and B31.3 requirements.

21. Do I need to create a new weld procedure when purchasing the SWR? Can customers use

Novarc’s PQRs as-is?

ASME IX Code is quite clear that each organization must develop and qualify their own WPS/PQRs and Welding Operators. Novarc can assist customers with those activities and utilize its qualified WPS/PQRs for reference/baseline. However, customers cannot use Novarc’s WPS as-is for their production purposes as that would be a regulatory non-compliance.

22. How can I monitor the production?

The SWR comes with the NovData™ production monitoring software that produces daily reports. The daily report includes: production time, welding time, pipe diameter and more. It also creates a time-stamped log file with voltage, current, WFS, travel speed and all other relevant weld and motion parameters for each weld.

The SWR also comes with a camera built into its robotic arm. With this feature, operators get a clear view from inside the groove on the HMI as each weld progresses in real time. Novarc’s welding vision system records all videos for future analysis.

23. What shielding gas is required?

Welding shielding depends on the weld process and filler metal. Our technical team can assist you with specific welding applications. The recommended gases for Carbon Steel pipes are the following:- Solid wire: 85% Argon 15% Co2, or 90% Argon 10% CO2

– Metal core: 90% Argon 10% CO2, or 98% Argon 2% CO2

– Flux core: 75% Argon 25%, or 100% C02

24. What are the power and air requirements for the SWR?

The SWR needs 3 phase power and minimum 85 PSI compressed air. The electrical power can be any of

the standard voltages between 208V and 600V.

25. How does the robot connect with the rotator?

We replace the existing positioner/rotator motor with a servo motor so the SWR would be able to control it.

26. How does the safety system work?

The SWR has built-in speed and torque monitoring systems that ensure speed and forces are within required levels at all times.

27. How much maintenance is required for the SWR?

The SWR is designed to be a robust machine. As a result, only minimal maintenance is required. Maintenance training is included with the robot training. Maintenance is similar to a standard welding machine.

28. Can the SWR be moved around the shop?

The SWR needs to be anchored to a minimum 6’ concrete slab. However, you can move it between previously installed base locations using overhead cranes.

29. Can the SWR be used outside the pipe shop?

The SWR is designed for indoor usage. It can be used in the field or in a work yard, provided it is protected from the elements and within the temperature range of 5 – 50 degrees Celsius.

30. Can you copy data from one SWR to another?

Yes, you can easily copy the data from an SWR to another using a USB.

31. How heavy is the SWR?

Approximately 3500 lb.