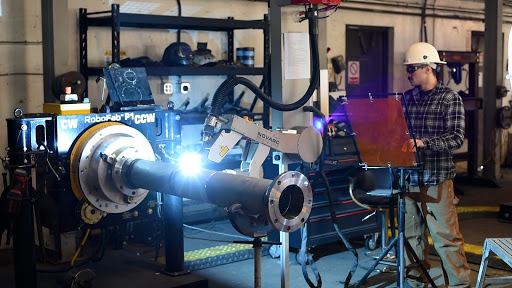

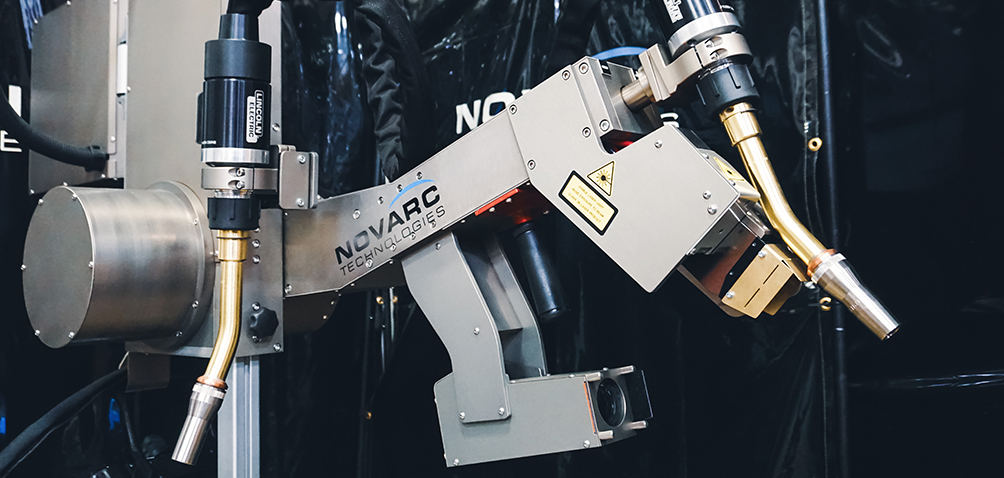

The Spool Welding Robot (SWR™) is a welding cobot designed specifically for pipe, small pressure vessel, and other types of roll welding. Companies that have invested in the SWR™ have increased their pipe welding productivity to 200-350 diameter inches per shift on carbon steel pipes, and 569-998 diameter inches per shift on stainless steel, and have dropped their repair rate to less than 1%. This is making our customers more competitive when bidding on jobs, and it has increased margins on contracts they’ve already won.

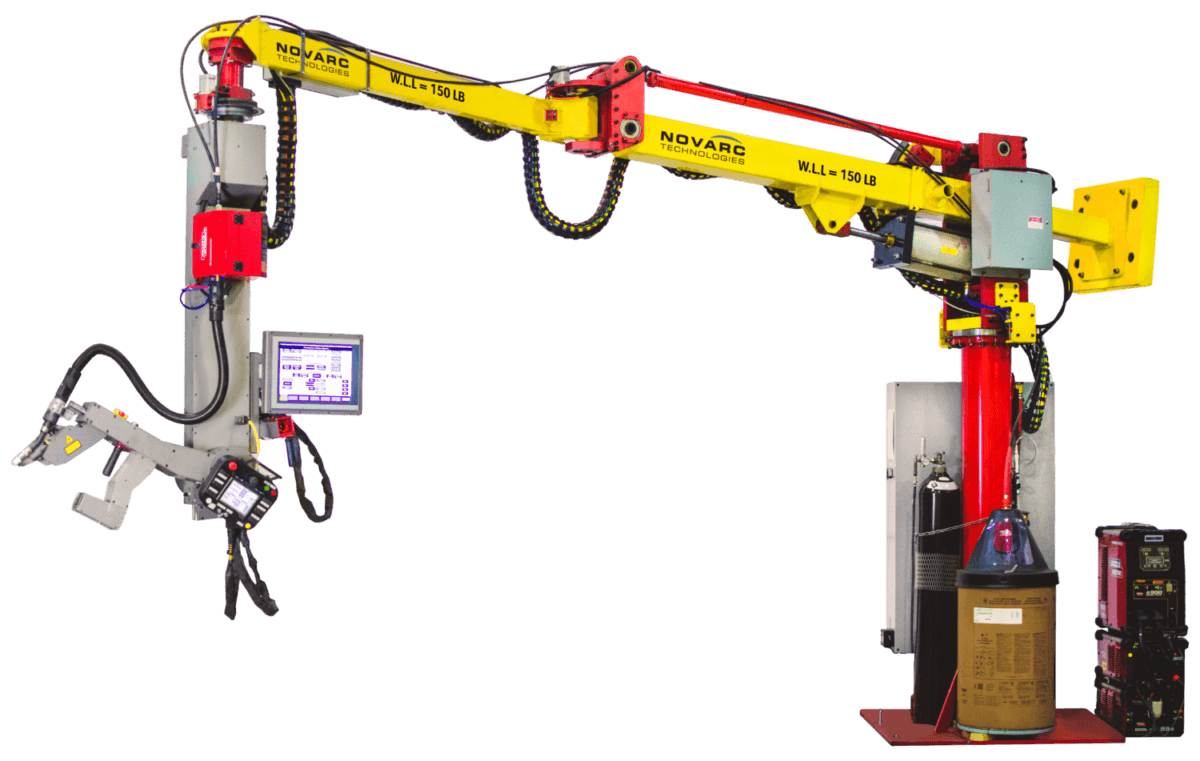

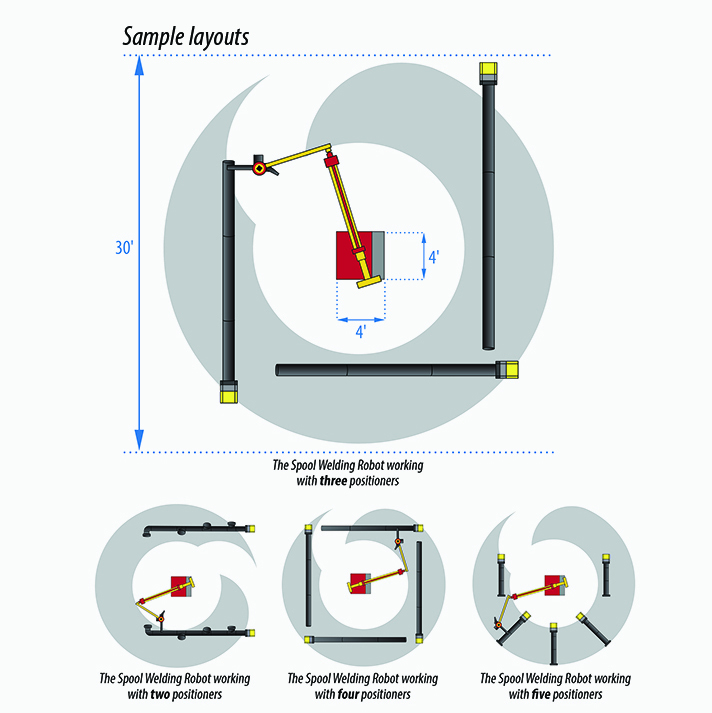

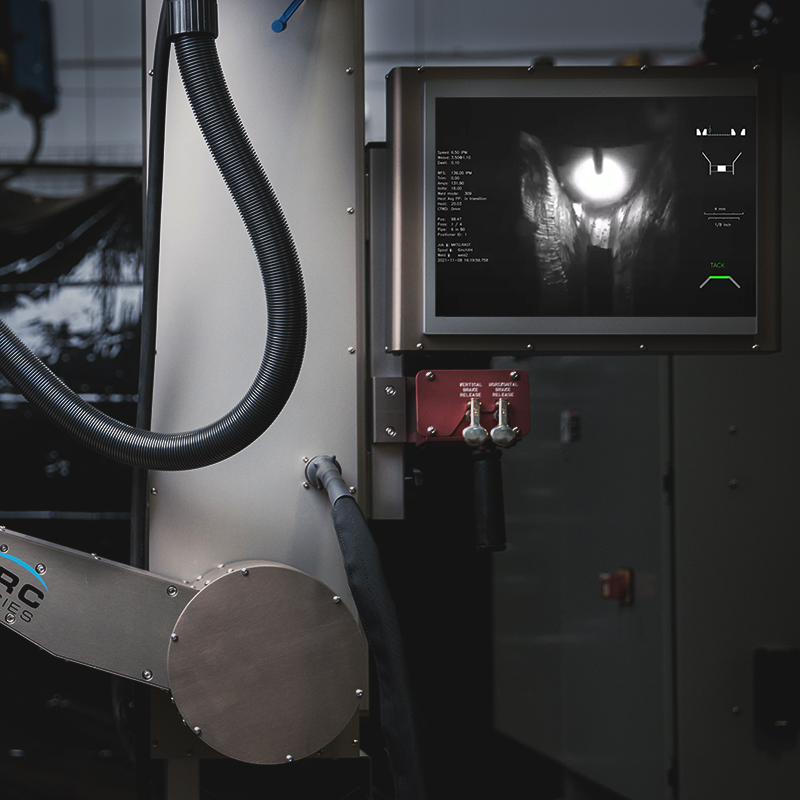

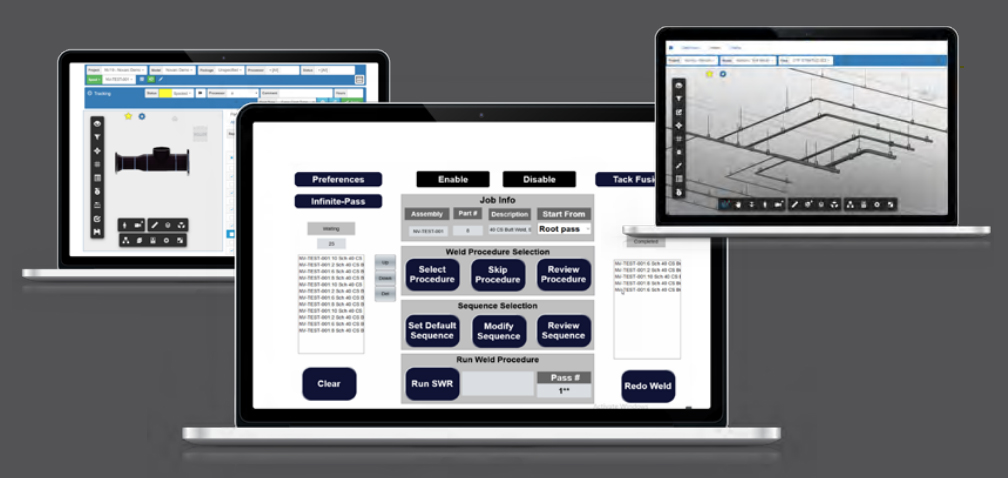

The SWR™ has the smallest footprint in the industry and when you combine our proprietary Welding Vision System with the insights provided from NovData™, you get a world-class solution that will make you more competitive in your market.