In the never-ending process for fabrication shops to become more efficient, profitable, and competitive, the need for detailed data and reporting is now a critical part of business.

Remember, the data does not lie.

However, management should always ask, “how is this data actionable?”

Your decisions are only as good as your data. All the facts and statistics in the world won’t do you any good if you can’t access them easily or understand them within their broader context. No matter how much info you’ve got, if you can’t effectively action it, it’s no good.

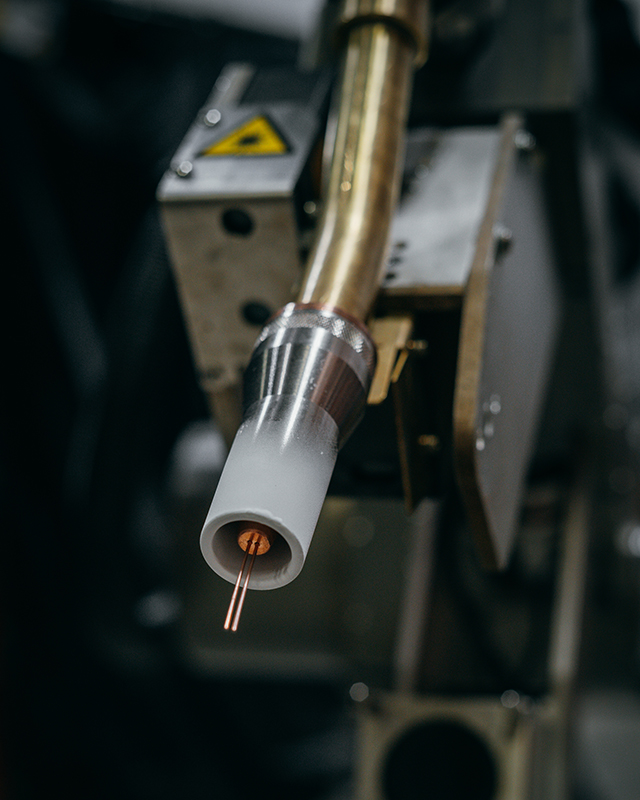

Traceability into your SWR production by automatically creating in-depth production reports should be standard process for a business. Today a shop needs to understand how to tie in the weld data and video logs to track and improve pipe welding productivity. This is further enhanced when daily operational reports can also be automatically generated.

Understanding and actioning your data allows shops to bid competitively on projects by applying cost savings gathered from daily operations reports. At a deeper level, manager can track the critical weld parameters for accurate troubleshooting and enhanced quality control too. Even log reports should be available for each weld.

Let’s connect and start the conversation on how data and reporting will help you to become more efficient and profitable.