While the salesman jokes are always good for a classic laugh, we have seen some very interesting trends in the cobot and welding market over the last 18 months, directly from the sales professionals who have been in virtual meetings and are back on the road again connecting with customers face-to-face.

Typically, there is a long list of SWR benefits a sales representative can focus on, to help support a fabrication shops business process improvement. Hot topics like improved efficiencies, managing within a labor shortage, improving weld quality and making a business more competitive.

Regularly, there are two very important topics that are passed over quickly by fabrication shop buyers and Executives, that are very important when you look closer at both the short and long-term return on investment.

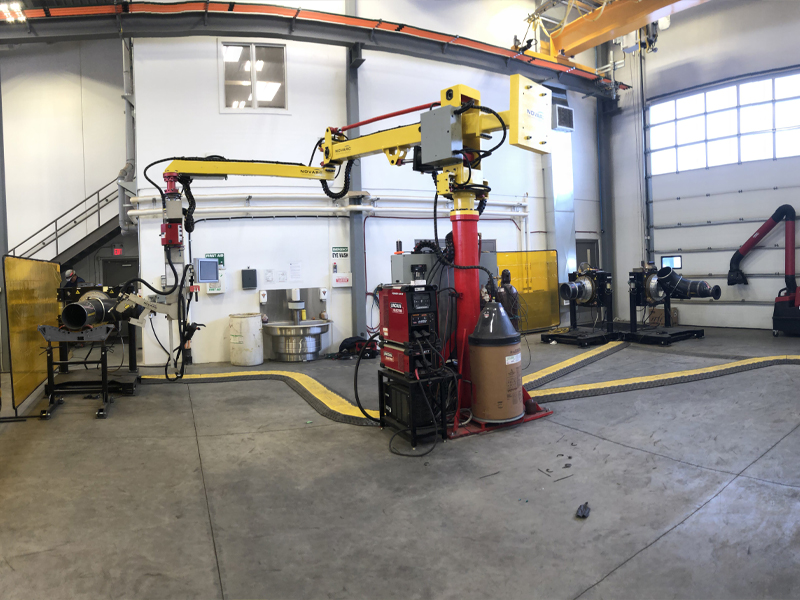

With a footprint as small as 4’ x 4’, an SWR can be small enough to fit anywhere in your shop without the need to change your current shop workflow. Every shop has unique needs, and a small footprint offers two key factors. First, it’s flexibility of size means it can be positioned anywhere in a shop, against the wall, in the corner, or in the middle of the floor. Second, it creates a flexible future for a shop if there is a requirement to change a floor layout, and space turns into a premium as a shops capacity grows and their space fills.

100% focus on SWR – Spool welding robot vendors will typically spread their product focus across multiple product lines with 5 or 10 different areas of focus. This approach is inherent with challenges that unfortunately trickle down to the users of the products. When a vendor sharpens and refines their focus on creating one really awesome product, they avoid all the distractions of building, managing and selling multiple products.

This will usually see a vendor rise to the top of their niche market space, delivering a much higher quality SWR than any others in the market. With just one product to focus on, enhancements, new versions, quality, customer support and over-all business process becomes an industry benchmark for others to keep pace with.

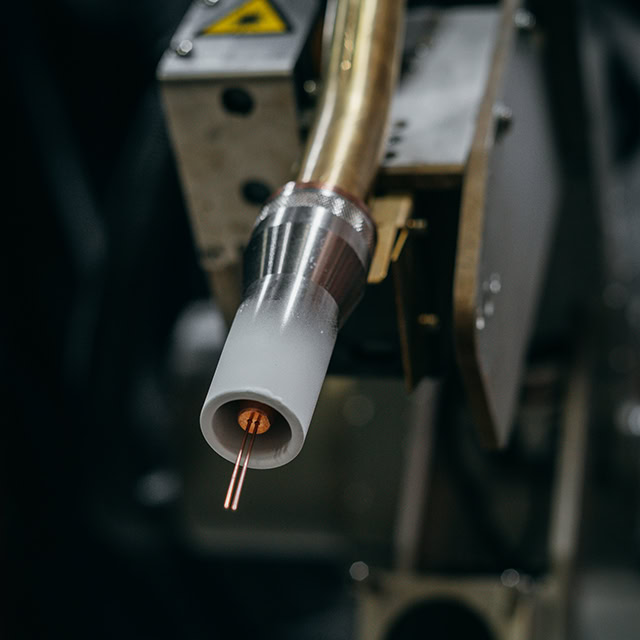

With a razor-sharp focus on one product, and looking closer at an SWR footprint, fabrications shops will only benefit when they decide to look a little deeper into the little things that really make a difference.

Let’s connect and start the conversation on how the little things will help you to become more efficient and profitable.