Offshore Case Study

“You kind of get a triple effect when you look into the ROI situation in that I’m using lower labor, building it faster, and my overall cost is cheaper. Essentially I can produce more units in the same footprint.”

Challenges that Forced them to Investigate New Solutions

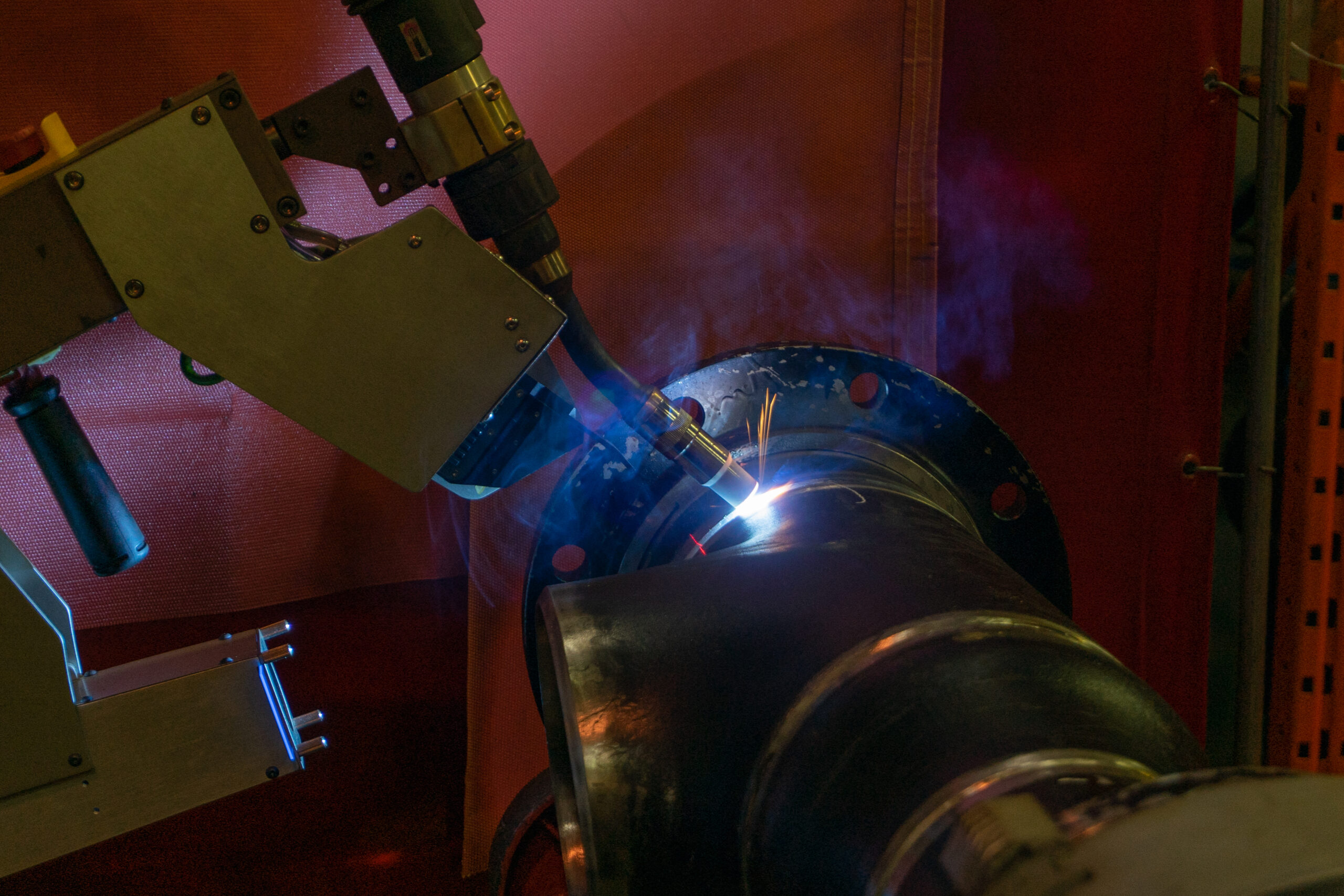

Offshore platform construction and maintenance is a challenging, high-risk work. Welders working on these projects are at risk from injuries due to UV light, radiant and excessive heat, carcinogenic fumes and arc flash. Combine these risks with a work environment that includes heavy equipment, suspended loads, rough terrain and extreme weather conditions, and there is an obvious cause for concern.

In addition to safety concerns, the welding industry is faced with a shortage of skilled welders as many are retiring, and not enough young laborers are entering the profession. And then there’s the competitive nature of fabrication shops serving the manufacturing industry.

The dwindling supply of qualified labour in the welding industry is a significant issue for pipe fabricators in both North America and Europe, which is accelerating the need to automate. More automation can free up skilled welders from doing repetitive work, enabling them to do the more difficult welds. “The cost of labor is rising and labor is getting scarcer, so more companies are moving towards automation because it’s the only way to survive. If they don’t invest in technology automation, then they probably won’t be around in another 10 years.”

Many have seen the benefit of investing in flexible automation in order to increase their competitiveness, and their bid rate on projects.

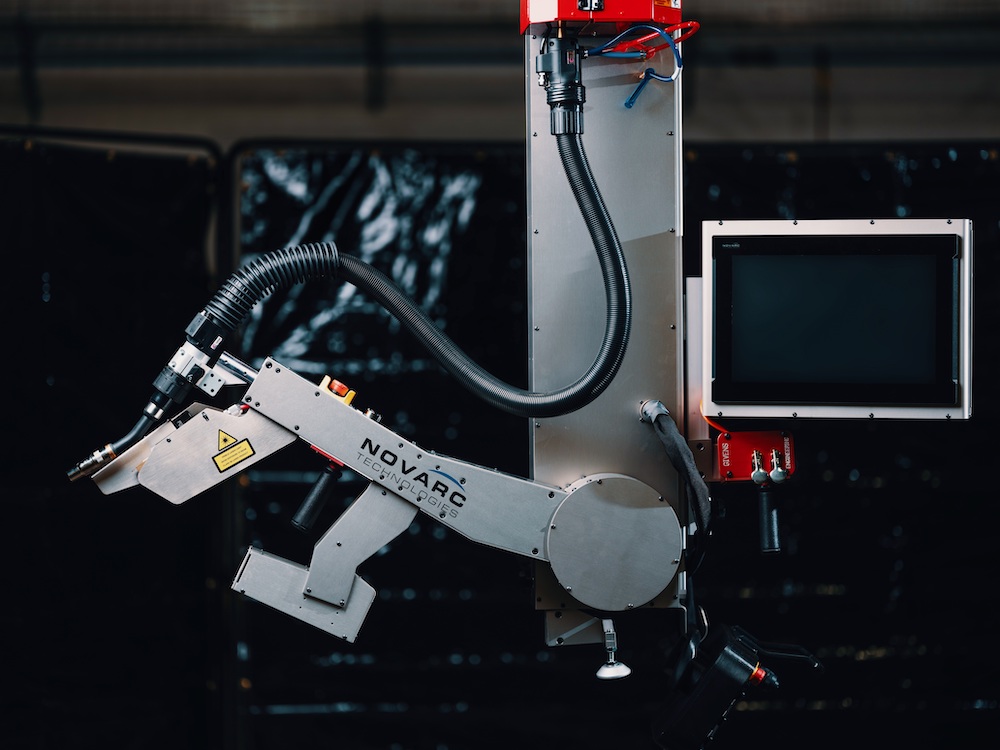

Novarc’s Spool Welding Robot (SWR) Solution

Novarc works with pipe fabricators that are looking for ways to lower their cost per weld to make them more competitive in the industries they serve. The SWR’s patented technology makes this a Cobot that is user-friendly and designed to promote safety, increase productivity, enhance weld quality and reduce pipe welding costs while providing pipe fabrication shops an affordable path to automation.

Novarc’s SWR doesn’t abandon the human operator, instead, it works alongside the welder, allowing those with less skill and experience to do the job that only senior welders could perform. The results are welds with greater precision, accuracy, speed and a never before achieved balance of productivity and quality.

The Bottom Line

With Novarc’s SWR, our customer has been able to produce more units on the same shop footprint. The facility on average welds about 500 spools a week, in a 100’ x 100’ building. A typical pipe shop is about three times that size and has the same production rates.

Increased Safety

Safety is a huge concern in the oil & gas and pipeline construction industry, and it’s understood that work is awarded to fabrication shops that have a clean record and adhere to strict safety standards. “When you start putting more automation into the welding process, it practically eliminates human error. That’s a big driver into lowering costs, providing a safer place to work and a more consistent, better quality end product. And the SWR allows you to stay within code and is very precise, and very fast.”

User-Friendly

“There’s nothing that I’ve seen in the market in the last two years to even come close. What sets Novarc apart is the ease-of-use of the tool and the fact that it is user friendly. The SWR has the end-user in mind. Once you buy the robot, you have the tech support and everything to assist you so you’re not standing alone. And on top of that, it’s hard to replace the machine once you have it, because there’s nothing really that can weld much faster or better.”

With the ease of use of the SWR, the company executive said, “The cost of labor to perform our welds decreased significantly – we could use a young welder, a fifth class fitter, to make our welds. So there’s an added gain in needing fewer people to perform higher quality welds.”

World Class Support

“The robot software allows Novarc to live link into the data to remotely access and see the same issue you’re seeing. This means you don’t have to verbally explain over the phone. They visually see the maps and the coding behind it as the SWR is operating to see the glitches, if there are any, and also help diagnose the kinks from remote access. This allows for very fast problem solving, and not having to miss something in translation or incorrectly explain the issue.”

About Novarc Technologies

Novarc Technologies is a Canadian-based robotics company specializing in the design and commercialization of collaborative robots for industrial applications. Novarc’s Spool Welding Robot (SWR) is the world’s first of its kind in pipe welding application. Novarc’s SWR has built a reputation for its unique form factor and advanced features for pipe welding not unlike a human’s precision and dexterity, with an operator-friendly user interface, adaptive control systems for accurate torch control, and machine learning algorithms to detect features.

As a proven pioneer in the field, Novarc has a dedicated team of engineers and scientists eager to solve challenging industrial automation problems that improve customers’ bottom line. The welding industry is looking to adopt these technologies in order to solve the shortage of qualified welders, accommodate the millennials workforce, and solve the cleantech challenges of this century.