Challenges That Forced Them to Investigate New Solutions

Like many companies worldwide, Trident faced significant challenges in the aftermath of the Covid-19 pandemic. As they had to reduce their workforce due to the economic impact, finding qualified welders became increasingly difficult. The shortage of skilled welders created a bottleneck in their operations. Recognizing the need for a solution that could bridge the staffing gap and enhance operational efficiency, Trident embarked on a search for innovative pipe welding technologies.

The SWR presented a solution by filling the gap created by labor challenges and offering automated processes to alleviate the struggle of finding qualified personnel. The desire to implement employee-friendly technology and streamline operations motivated the investment in the SWR as a solution to bridge the staffing gap and enhance efficiency.

“The primary hurdle we faced was finding a solution to bridge the gap and reduce our reliance on human welders. Remarkably, the SWR has proven to be equivalent to having four to six skilled welders on average for our operations.”, – says Chisam Hoedebeck, Director of Operations at Trident Process Systems.

Novarc’s Spool Welding Robot

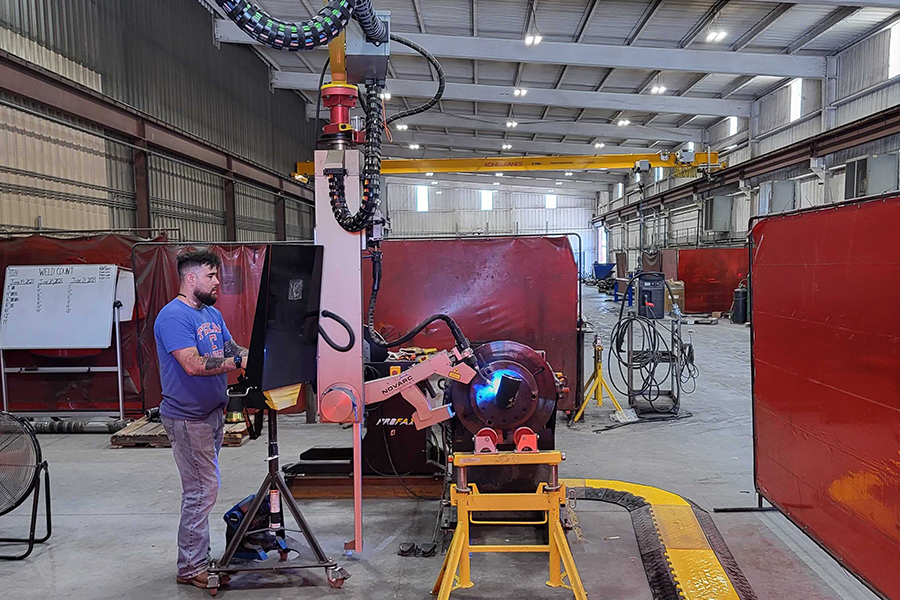

The Spool Welding Robot (SWR) is a cobot (collaborative robot), designed specifically for pipes, pressure vessels, and other types of roll welding. Being a cobot, the SWR combats the shortage of highly qualified welders and significantly improves shop productivity, and produces high-quality welds every single time.

“We evaluated a few different solutions and what truly set the SWR apart were its unique features. Firstly, it is specifically designed to weld pipe, and secondly, it has the capability to effectively weld open root pass”, says Hoedebeck. “Also, what really was appealing to us was the fact that we didn’t have to program or have somebody program the robot. All the recipes to weld different pipe schedules and diameters were already generated on the machine and available for us”.

The Bottom Line

Since implementing the SWR, Trident has been able to:

-

Increase their pipe welding productivity and achieve 200-250 extra diameter inches per shift

-

Lower labor costs by 10 to 20% (with some projects experiencing up to 50%)

-

Achieve 0% reject rates with the SWR since implementation

-

Combat the shortage of welders

Improve Profitability

Since integrating the SWR into their operations, Trident has experienced a significant increase in pipe welding productivity, achieving an average of 200-250 extra diameter inches per shift.

Furthermore, the adoption of the SWR has resulted in substantial cost savings, with Trident lowering their labor costs by 10 to 20% across various projects. In some cases, the savings have reached an impressive 50%, contributing to improved profitability and a stronger bottom line.

Improve Weld Quality

In addition to the financial advantages, Trident has witnessed a remarkable enhancement in weld quality. Since implementing the SWR Trident has maintained a 0% reject rate on welds made with the machine. This level of weld quality not only ensures customer satisfaction but also minimizes rework, saving valuable time and resources.

Close the Labor Gap

One of the most significant benefits Trident has realized through the adoption of the SWR is the ability to close the labor gap. The shortage of skilled welders has been a pressing issue in the fabrication industry, impeding growth and hampering productivity. By incorporating the SWR into their pipe welding department, Trident effectively expanded its pipe welding workforce capacity by 1.5 times.

“We’re very impressed with the system. I feel like we should have bought one five years ago”, says Hoedebeck.

World-Class Support

Throughout the implementation process, Novarc proved to be a trusted partner, demonstrating transparency and providing unwavering support to Trident.

“Since the beginning, Novarc was very transparent with us on a lot of things, like having to substitute some of the mechanical parts, due to availability and they worked around the clock with us to make sure that we are getting this machine where it needs to be. I could really tell that it was Novarc’s priority to get us up and running. I’ve done a lot of integration projects like this, but this has been by far the best one because of their communication and support”, says Hoedebeck. “After having the SWR system for only six months we’re already expanding this machine with more weld stations”.

About Novarc Technologies

Novarc Technologies is a full-stack robotics company specializing in the design and manufacturing of cobots and AI-based machine vision solutions for autonomous welding. Novarc’s Spool Welding Robot (SWR) is the world’s first of its kind in pipe welding applications. As a proven pioneer in the field, Novarc’s team is dedicated to solving challenging welding automation problems that improve customers’ bottom line.

Unlike other welding solutions, Novarc‘s flexible technology is capable of welding a variety of joints, with fewer space restrictions, where operators interactively make adjustments during the weld without the need to pre-program.