Challenges that Forced them to Investigate New Solutions

Ganotec-Muga Fab approached Novarc because they needed:

-

To overcome the challenge of finding skilled labour

-

To increase fabrication shop productivity with less welders

-

To find a solution that would allow an average welder to produce the same quality while increasing the quantity of welds as a highly skilled welder

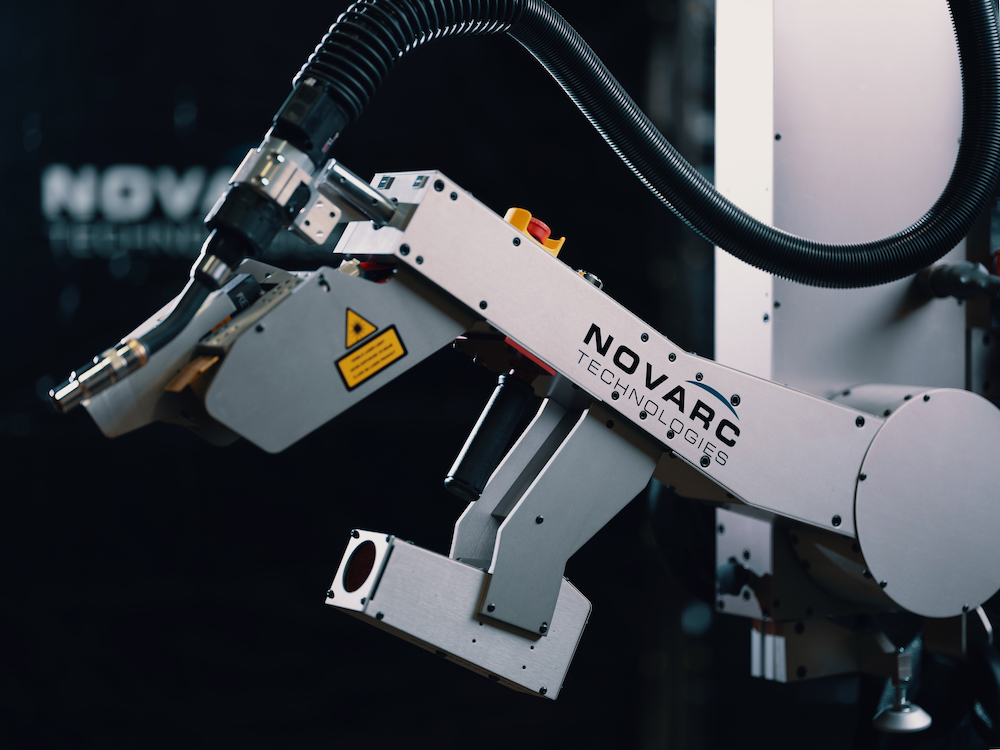

Novarc’s Spool Welding Robot (SWR) Solution

With the smallest footprint in the industry, the Spool Welding Robot (SWR) is a collaborative welding machine designed specifically for 1G welding. Companies that have invested in the SWR have increased their pipe welding productivity by 2 to 3 times, depending on the material grade, size and thickness, and have dropped their repair rate to less than 1%. This is making our customers more competitive when bidding on jobs, and it has increased margins on contracts they’ve already won. The SWR is also allowing our customers to bid on projects they never would’ve considered before. Now they can go after projects that have short delivery timeframes as well as other projects that they wouldn’t have had margin to bid on.

When they came across Novarc, Ganotec-Muga Fab was looking for a solution that would address their challenges around increasing shop productivity and finding skilled labour.

“We looked at a few other options when looking for welding solutions. The edge that Novarc has is the footprint of the equipment, we have a lot more flexibility with the SWR. If the average pipe size of the shop is really small, we can just park the equipment and it does not take a lot of square footage”, says Martin Cartier, Director of Ganotec-Muga Fab.

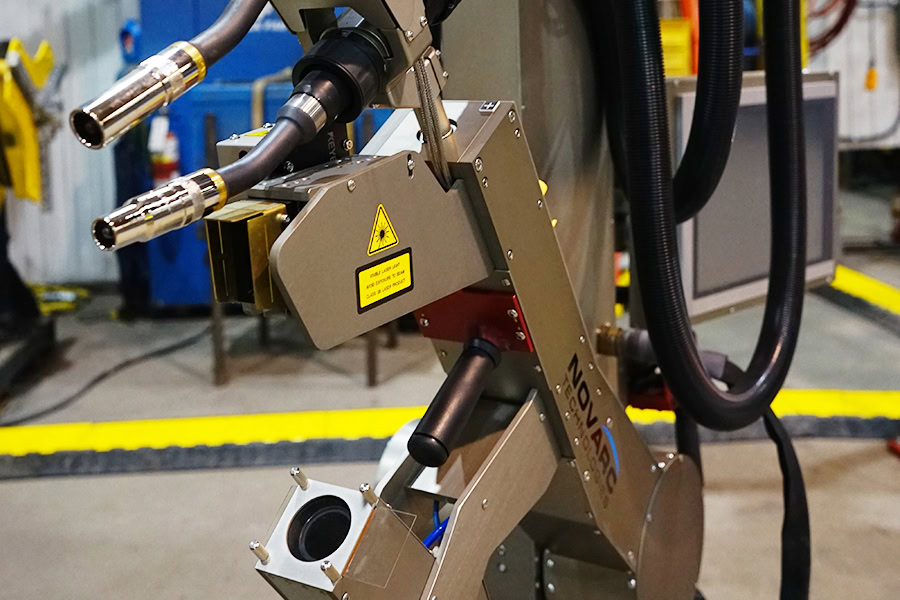

“The other reason why we went with Novarc is that Novarc showed up here with what we call a “fresh air”. A new product that is really dedicated to improving pipe welding. When we purchased the equipment we were their first client to order the dual feeder welding arm, we were the first (dual torch) unit that Novarc built. We always worked together to meet the goal and to get the equipment improved depending on our needs. I really feel that from the beginning it has been a partnership and not only a client-supplier relationship”, Cartier added.

“We are working in a market (oil and gas) that is very hard to implement new technologies due to the changing oil value. But so far our clients, including TransCanada Energy and Irving Oil, have all approved it because we proved that we took our time to learn about this equipment, and so far we have been very successful”, Cartier added.

The Bottom Line

With the Novarc SWR, Ganotec-Muga Fab has been able to increase their pipe welding productivity by 220-300%, lower their repair rates to 0.5%, reduce dependency on highly skilled welders, and increase margins on the projects they have already won.

Productivity Improvements

Since purchasing the SWR, Ganotec-Muga Fab has increased their welding productivity by 220% on standard wall pipes, and 300% on heavy wall pipes compared to manual welding.

“For standard pipe thickness, we found that it’s a ratio of 2.2 welders to 1 SWR. So to produce the amount of Factored Diameter Inches (FDI) produced with the SWR, we will need 2.2 welders”, says Cartier. “And for heavy pipe walls the ratio is about 3 welders to 1 SWR”.

Quality Improvements

In North America the average repair rates at pipe fabrication shops are between 3-5%. The SWR brings this down to less than 1% by producing consistent, high quality welds. For fabrication shops producing 6,000 welds per year with a 3% repair rate, they are likely spending around $180,000/year in repairs. By reducing the repair rates to 0.5%, customers can recover around $150,000/yr back onto their bottom-line.

“For the past 10 years, our repair rates for the fabrication shop have been just below 2%. But if we are looking at just the SWR, the repair rate is about 0.5% when welding 12” – 36”, carbon steel and chrome pipes”, says Cartier. Muga Fab is fabricating piping in accordance with ASME B31.1, ASME B31.3 & CSA Z662.

Reducing Dependence on Highly Skilled Welders

With the Novarc SWR, Ganotec-Muga Fab has been able to overcome their main challenges of finding skilled labour, and implementing a solution that would allow an average welder to produce the same quantity and quality of welds as a highly skilled welder.

“We did not assign our top welders to the SWR because the goal was to bring an average welder to the level of a top welder, and produce the same quality weld. It took about a week to a week and a half for our welders to become comfortable using the SWR. There is no need to rely on highly skilled operators”, says Cartier. “We are assigning our highly skilled welders to the more complicated tasks.”

Increase Margins on Projects

Ganotec-Muga Fab is achieving significant productivity improvements with their SWR, which is making them much more competitive in their market and increasing margin on jobs they’ve already won.

“The SWR has increased the margins on the projects that we already have; and the way we are aligned for the next project is that we would put the same cost in our estimate because in the market that we are working in, we are the only one with this equipment”, says Cartier.

About Novarc Technologies

Novarc Technologiesis a Canadian-based robotics company specializing in the design and commercialization of collaborative robots for industrial applications. Novarc’s Spool Welding Robot (SWR) is the world’s first of its kind in pipe welding application. Novarc’s SWR has built a reputation for its unique form factor and advanced features for pipe welding not unlike a human’s precision and dexterity, with an operator-friendly user interface, adaptive control systems for accurate torch control, and machine learning algorithms to detect features.

As a proven pioneer in the field, Novarc has a dedicated team of engineers and scientists eager to solve challenging industrial automation problems that improve customers’ bottom line. The welding industry is looking to adopt these technologies in order to solve the shortage of qualified welders, accommodate the millennials workforce, and solve the cleantech challenges of this century.