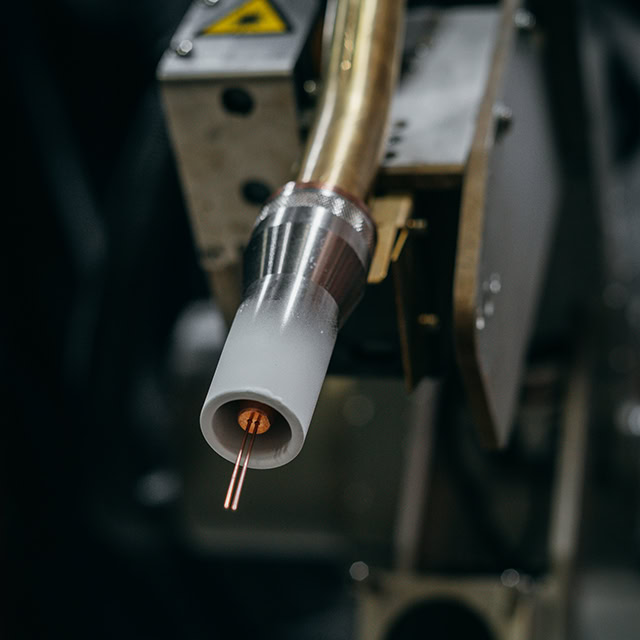

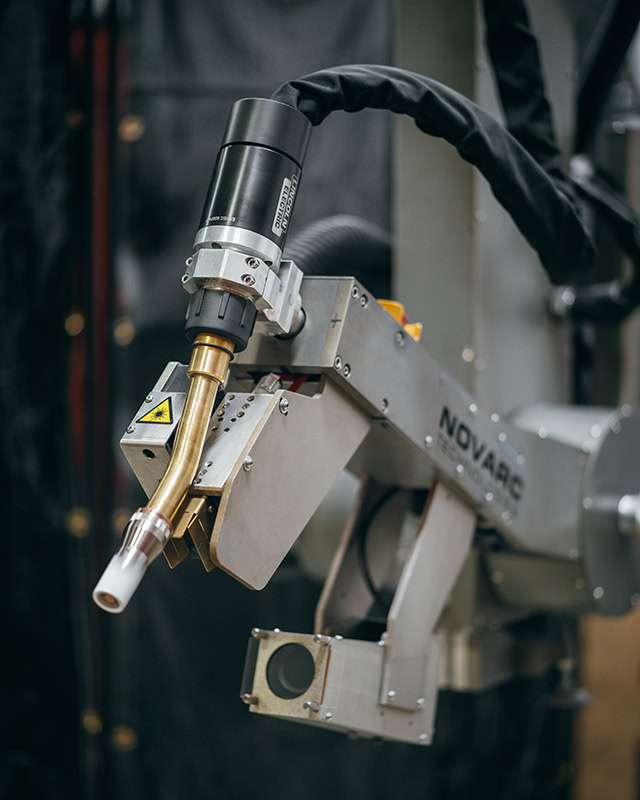

SWR™+HyperFill® is a game-changing technology for companies that are looking to beat their competition. It is a highly efficient, fully integrated dual torch system that utilizes Lincoln Electric’s patent-pending twin-wire GMAW solution, HyperFill®, to maximize productivity and profitability for our customers.

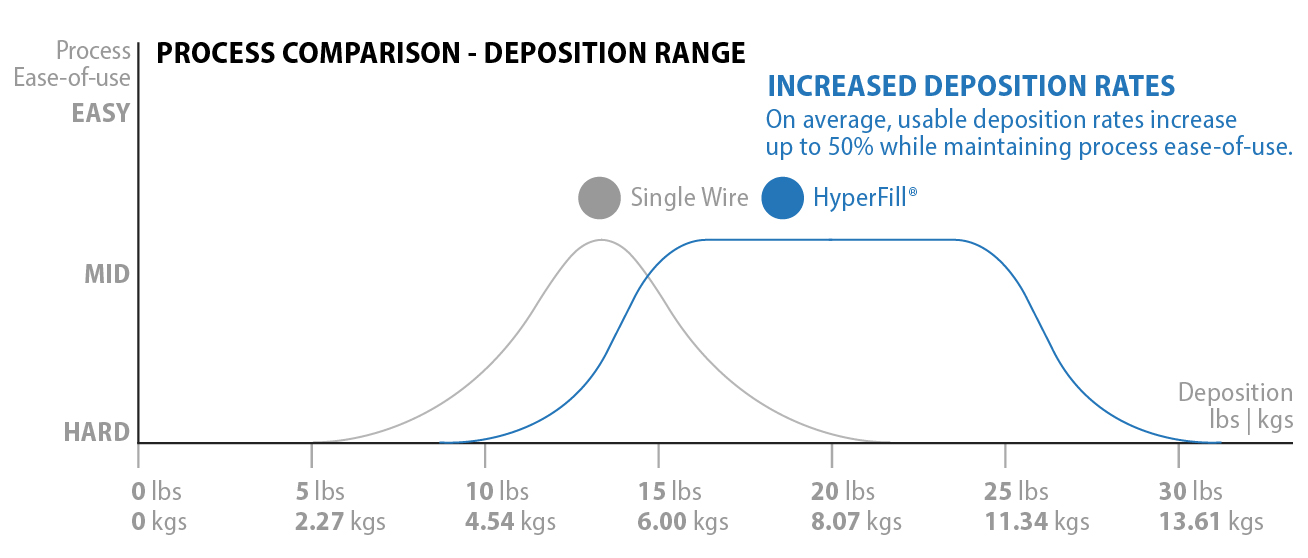

With the HyperFill® option, fabrication shops can expand the capabilities of their SWR™. The system increases heavy fabrication productivity by increasing weld deposition rates while delivering excellent weld quality.

It uses the Lincoln STT GMAW process on the root, and twin wire (HyperFill®) on fill and cap passes, and it can be used on carbon steel pressure process pipes or vessels with 0.5”-2.5” thickness and as low as 6” in diameter. The system also has the flexibility of using root to cap GMAW or seamlessly switching to FCAW or MCAW for the fill and cap passes.