Published by: BIC Magazine

The following is an excerpt from this article

North America is facing an ominous demand for infrastructure.

The National Association of Manufacturers stated that nearly 81% of manufacturers are unable to hire the number of welders they need. Also, the American Welding Society predicts there will be a shortage of 314,000 welders in the U.S. by 2024. The fabrication industry is facing huge obstacles supplying industries that are building this infrastructure and is looking at robotic welding and a path to automation to solve this challenge.

Before a fabrication shop can make a decision on the optimal automation solution, key issues need to be considered such as production mix, infrastructure needs, human resource requirements and ultimately, the ROI. It needs to choose pipe welding automation systems that will help achieve consistent, high-quality welds, while increasing a shop’s productivity so it can get ahead in an increasingly competitive market.

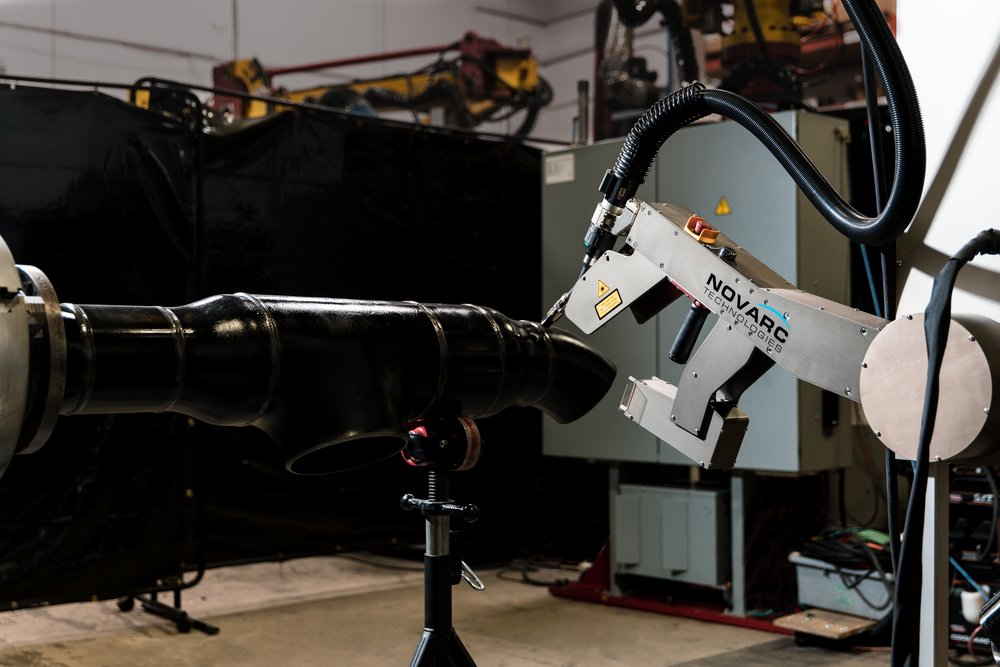

Novarc Technologies, a pioneer in the field of collaborative robotics, has developed a breakthrough solution to this difficult challenge — the world’s first welding cobot, or collaborative robot: the Spool Welding Robot (SWR™). It is the first of its kind in pipe welding applications.

The SWR™ allows customers to deliver projects faster, at a lower cost and with better quality welds. With Novarc’s pipe welding automation system, customers are able to target those bigger projects and improve delivery timelines, capacity and margins.