Published by: SNIPS Magazine – January 15, 2020

By: Emell Derra Adolphus

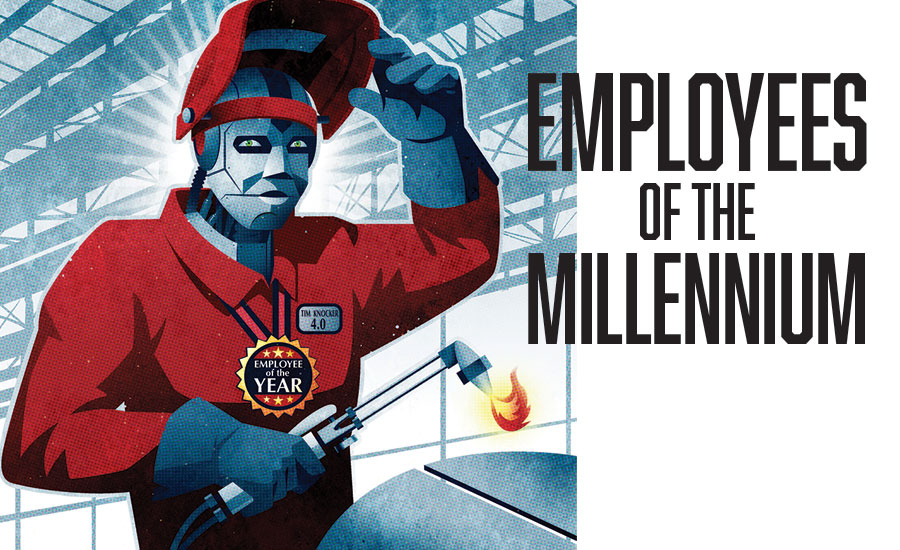

The Novarc collaborative Spool Welding Robot (SWR) is an ideal employee and it will only improve with age and upgrades. Although the SWR works longer, faster than any human can, human interaction is still essential element to its operations. Advanced automation technology helps it produce fast, efficient and repeatable quality welds every time. A built-in safety system ensures the SWR always operates within safe speeds, pressures, and eliminates the need for fencing around its workspace. If anyone, or anything, should bump the SWR while it is working, it immediately ceases all operations — a failsafe that is proven to make the SWR a safer employee than your average Joe. Yet for many skilled tradespersons, taking bumps is an implicit part of their job.

On any given day, human welders face hazards such as arc flash, carcinogenic fumes, UV lights, and excessive heat. Collaborative robots (cobots) like the SWR can significantly reduce wear and tear on a welding team while helping everyone work and breathe easier. The SWR’s efficiency cuts down the release of toxic gasses and its turnkey technology can extend the careers of welders who have lost hand skills, keeping their knowledge and standards in the trades. As alien as its technology may seem, the SWR was created to complement a workforce. Not conquer. If only it can convince all mechanical contractors that it truly does come in peace.

Robots ≠Cobots > Humans

Novarc’s Spool Welding Robot (SWR) is for the heavy-duty, continuous welding of pipes, small pressure vessels and other types of roll welding.

“Whereas industrial robots generally replace human workers and threaten their job security, collaborative robots work alongside operators,” explains Soroush Karimzadeh, CEO of Novarc Technologies, a Canadian-based robotics company specializing in the design and commercialization of collaborative robots for industrial applications. “(They) are capable of creating more jobs by allowing less experienced operators perform the tasks than can only be done by highly skilled workers. By using the SWR in the fabrication shop, the managers can redeploy their high-value labor to other key projects, while lowering the cost of their roll welding operations.” Read More…